Welcome to Club SAITO !

I have only converted one, It was a beautiful landing, perfect flare, just wasn't on the runway, missed it by a foot, landed in the freshly tilled field right next to it.

I use nylon screws to attach fixed aluminum gear. Makes them "ROL" gear.

Retract On Landing. Especially on unintentional landings. Really good at those.

Retract On Landing. Especially on unintentional landings. Really good at those.

"Improved" or revised?

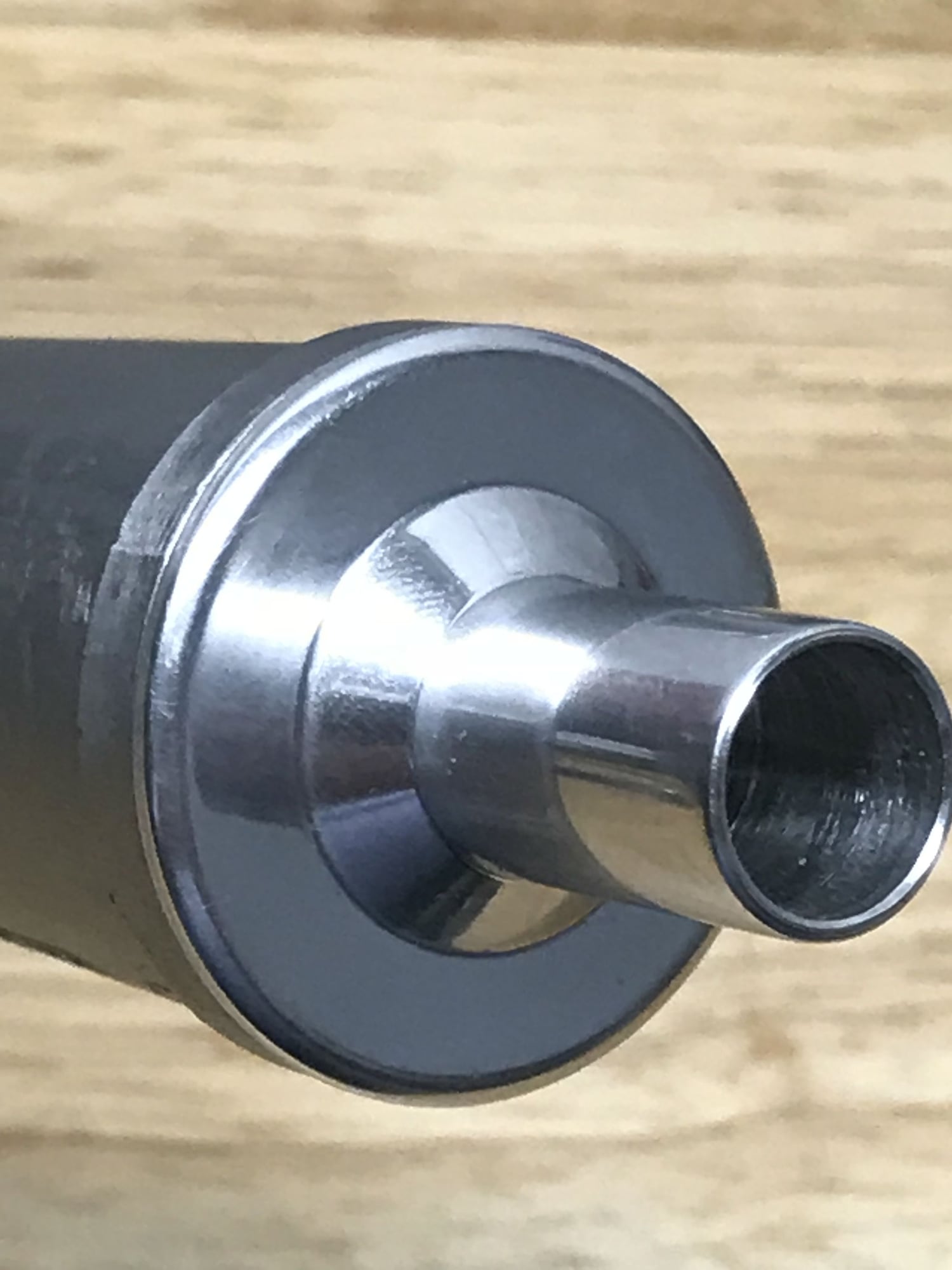

AFAIK the main difference is the angle of the inlet connection on the 65 to 82 mufflers anyhow. The later version was about 20° off axis and the early version was about 85° off axis.

I never noticed any performance difference between the two, maybe Dave's test sessions show otherwise.

AFAIK the main difference is the angle of the inlet connection on the 65 to 82 mufflers anyhow. The later version was about 20° off axis and the early version was about 85° off axis.

I never noticed any performance difference between the two, maybe Dave's test sessions show otherwise.

I always ask the same question when I make a new end cap. "Why did you leave the lock nut off?". Usually get the answer that they didn't think it was important. That thing grows and shrinks. Without the lock nut ,the screw works loose and goes away!

I am pretty sure you are right about the hose ring. The earliest had tapered outlets IIRC.

When those cast mufflers first came out, I called them "trash can mufflers" and traded them off. They really are pretty good as it turns out.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

I may be a weirdo but if the engine is at the larger engine of the mufflers range I drill three of the outlet holes 1/32" larger. Now I etch the size on them also because once you lay one down you can't be certain you're going to pick the correct one up again.

Not weird at all. At least, I hope not!

The replacement tail above is nearly 1/10" larger and the internal ports were enlarged as well. The tail pipe is a bit longer as well.

The replacement tail above is nearly 1/10" larger and the internal ports were enlarged as well. The tail pipe is a bit longer as well.

Got a thought that lead to a question. Hobbsy posted a shot of a page in a magazine that made an interesting statement concerning crankcase lubrication.

Indicated the front bearing sheilded both sides and the rear shielded on the back( crankpin side).

I have done lots if used e bay motorbearings on Saitos. I have not done any motor I bought new yet. In motors purchased new, what do you guys find concerning shielding in motors factory assembled.

And secondly, the article indicated the crankcase vented between the bearings via the nipple (factory) between the bearings in the bottom of the case.

Wonder if the motors that vent through the rear cover may be shielded different?

What have you noted Saitoheads?

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

Open bearing

Shielded bearing

Sealed bearing as in most front bearings

Not all bearings are have the front seal, Fox, MOKI and MVVS have no front seal.

Last edited by Hobbsy; 03-19-2019 at 12:24 PM. Reason: Spelling

i haven't found a sealed bearing in one of em yet. Just shielded with one or both sides removed...

Hey all

Got a thought that lead to a question. Hobbsy posted a shot of a page in a magazine that made an interesting statement concerning crankcase lubrication.

Indicated the front bearing sheilded both sides and the rear shielded on the back( crankpin side).

I have done lots if used e bay motorbearings on Saitos. I have not done any motor I bought new yet. In motors purchased new, what do you guys find concerning shielding in motors factory assembled.

And secondly, the article indicated the crankcase vented between the bearings via the nipple (factory) between the bearings in the bottom of the case.

Wonder if the motors that vent through the rear cover may be shielded different?

What have you noted Saitoheads?

Got a thought that lead to a question. Hobbsy posted a shot of a page in a magazine that made an interesting statement concerning crankcase lubrication.

Indicated the front bearing sheilded both sides and the rear shielded on the back( crankpin side).

I have done lots if used e bay motorbearings on Saitos. I have not done any motor I bought new yet. In motors purchased new, what do you guys find concerning shielding in motors factory assembled.

And secondly, the article indicated the crankcase vented between the bearings via the nipple (factory) between the bearings in the bottom of the case.

Wonder if the motors that vent through the rear cover may be shielded different?

What have you noted Saitoheads?

Some have said that leaving a shield or seal on the front side of the rear bearing is a good idea for the rear cover vented saitos. I've also read to leave it on the back side for the same reason, that it helps to retain more oil in the crankcase but it doesn't make much sense to me. The source of the oil is behind the rear bearing (ring blowby) and the place that needs the most oiling is the valve train. That's why saito moved the vent from the rear cover to the cam gear housing, or at least that's my understanding. Based on that premise I would install open retainer bearings in the rear regardless of vent location.

Last edited by Glowgeek; 03-19-2019 at 04:23 PM.

I replace the open front bearings on 2 strokes with sealed ones too, just to keep from sucking in debris from our grass runway. Not just dirt and sand but fertilizer too. Nothing like a little NPK to rust up the works!

My Feedback: (1)

I can't remember all the bearing variations in used Saitos I've rebuilt and never rebuilt one that was rear cover vented. 4 strokes have more positive crankcase pressure than negative (barely) so I install double sided sealed bearings in the front (2RS) to keep from spuing oil everywhere. In the rear I install open retainer bearings.

Some have said that leaving a shield or seal on the front side of the rear bearing is a good idea for the rear cover vented saitos. I've also read to leave it on the back side for the same reason, that it helps to retain more oil in the crankcase but it doesn't make much sense to me. The source of the oil is behind the rear bearing (ring blowby) and the place that needs the most oiling is the valve train. That's why saito moved the vent from the rear cover to the cam gear housing, or at least that's my understanding. Based on that premise I would install open retainer bearings in the rear regardless of vent location.

Some have said that leaving a shield or seal on the front side of the rear bearing is a good idea for the rear cover vented saitos. I've also read to leave it on the back side for the same reason, that it helps to retain more oil in the crankcase but it doesn't make much sense to me. The source of the oil is behind the rear bearing (ring blowby) and the place that needs the most oiling is the valve train. That's why saito moved the vent from the rear cover to the cam gear housing, or at least that's my understanding. Based on that premise I would install open retainer bearings in the rear regardless of vent location.

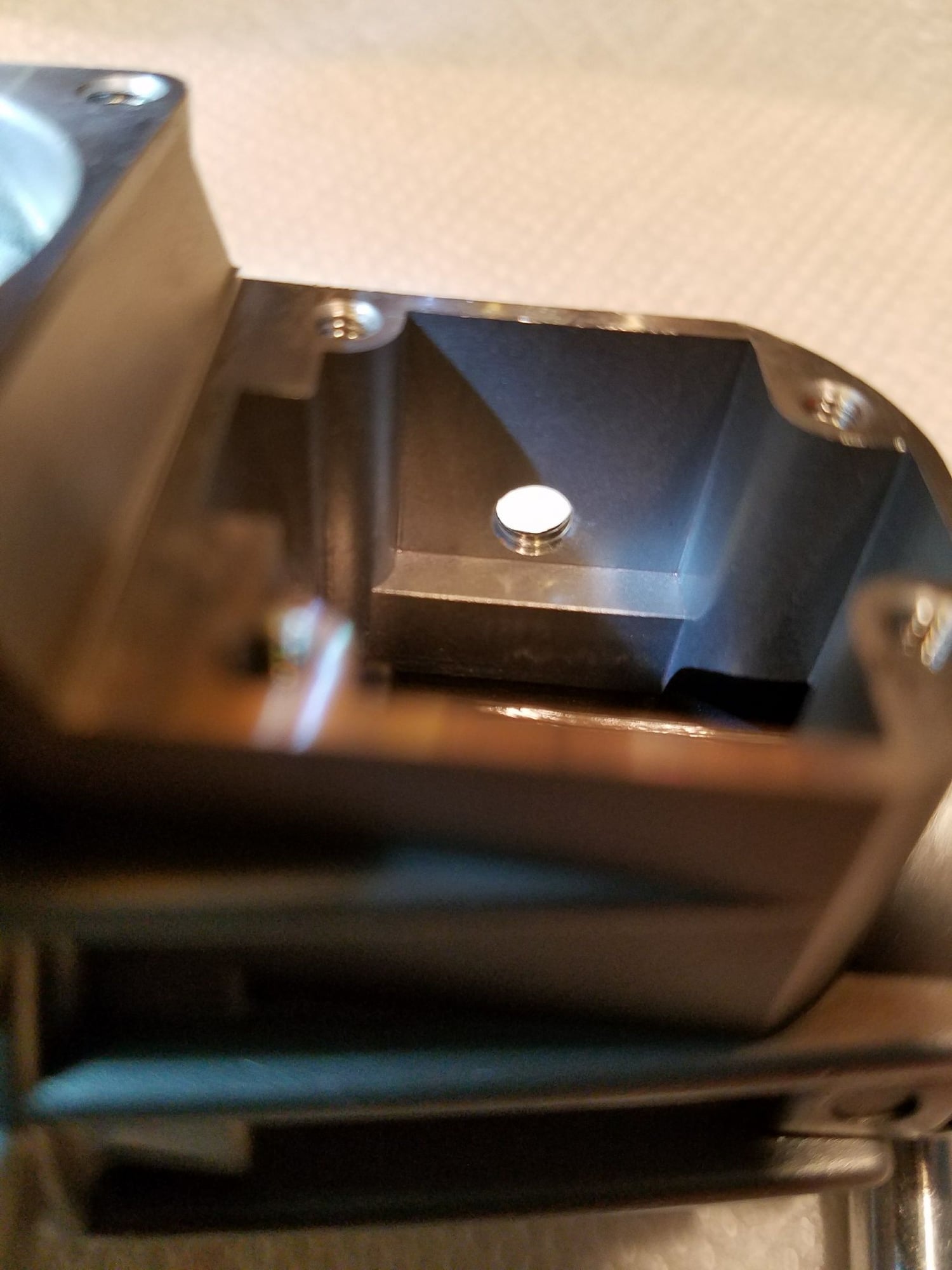

Glowgeek;, see what I did to my 2006 Saito 100>>

PS, I don't know why but the threads do not look good in the photos but they came out great, I made a wood jig to hold the case, I drilled the hole with my mill drill and used the mill shaft to align the tap wrench so the threads are strait as the hole. my cam will be well oiled

Jim

Last edited by the Wasp; 03-19-2019 at 07:55 PM.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

You'll never find one of those open front bearings that is not perfect and clean like those. A tiny bit of oil flows out of them, (which you'll never see) nothing flows in.

Jim, isn't that vent on the wrong side, I think it should be like these FA 40 a's

Yep,

The side you mention is the side I prefer, especially with side mounted engines with cylinder starboard. Inverted, it is about a draw. Probably not a huge difference however .

Jim, those threads show up clean and crisp in the pics I see, nice job.

Last edited by Jesse Open; 03-20-2019 at 03:42 AM. Reason: Add ancient pic

Well then, maybe my theory is wrong about 2 strokes. Perhaps the overall case pressure while running is higher than atmospheric? Wouldn't be the first time I was wrong. Lol.

My Feedback: (102)

Join Date: Dec 2001

Location: Colonial Beach, VA

Posts: 20,370

Likes: 0

Received 25 Likes

on

25 Posts

Fox 50 crank shaft with Labyrinth groove

You have to remember about two strokes that the seal is not the bearing's seals but the fit between the crankcase and the crankshaft and the film of oil that is there. Fox and several other brands actually have a spiral groove, (labyrinth groove) in the crank shaft that screws inward to keep that oil there. Interesting stuff. Gary has probably cut some of those grooves. John Deere tractors for years had only the labyrinth grooves as the out board seals.

Last edited by Hobbsy; 03-20-2019 at 04:59 AM. Reason: Add content

Hey Dave,

Actually what you have there is an Archimedes "screw" or helical seal. Yes, I have cut a few of them! They were used on many MG cranks as a main bearing seal. When we ground the cranks, at times that helical cut was needed.

Yes, I have cut a few of them! They were used on many MG cranks as a main bearing seal. When we ground the cranks, at times that helical cut was needed.

The Labyrinth seal use close fitting, mating grooves and ridges . The labyrinth seals are often used on high speed spindles where friction type seals may generate too much heat. Also benefit, like the helical seal from very low friction.

Similar but a bit different.

Actually what you have there is an Archimedes "screw" or helical seal.

Yes, I have cut a few of them! They were used on many MG cranks as a main bearing seal. When we ground the cranks, at times that helical cut was needed.

Yes, I have cut a few of them! They were used on many MG cranks as a main bearing seal. When we ground the cranks, at times that helical cut was needed.The Labyrinth seal use close fitting, mating grooves and ridges . The labyrinth seals are often used on high speed spindles where friction type seals may generate too much heat. Also benefit, like the helical seal from very low friction.

Similar but a bit different.